-40%

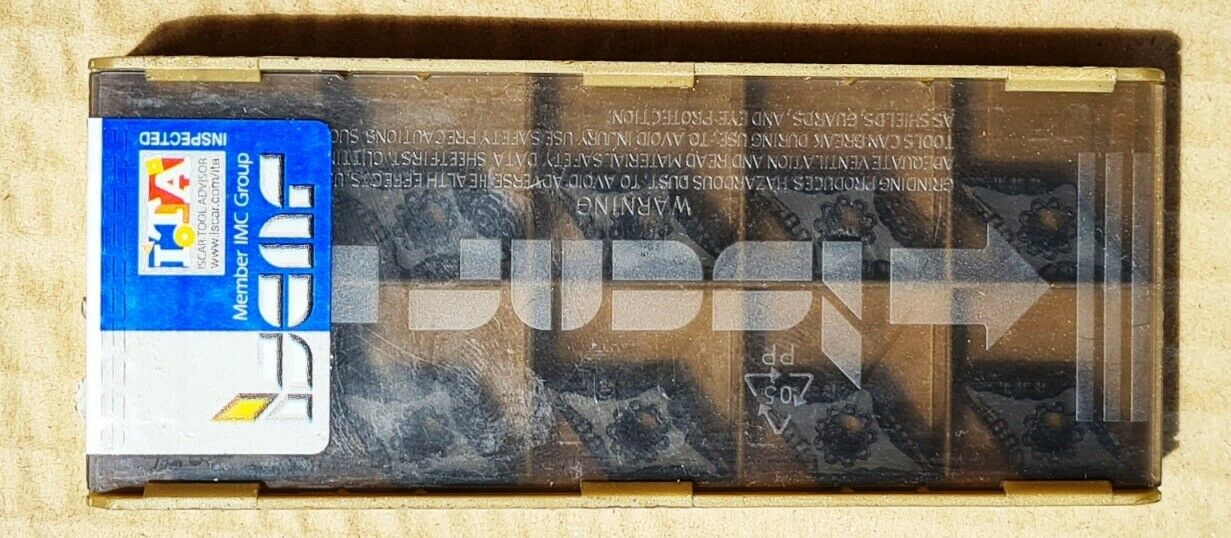

ISCAR DNMG 110404-F3P DNMG 331-F3P IC8150 10pcs 05560576

$ 15.83

- Description

- Size Guide

Description

Double-sided 55° rhombic insert, used for semi-finishing and finishing applications. Low cutting forces due to very sharp edge and positive rake.L

IC

S

RE

ft

(min)

ft

(max)

ap

(min)

ap

(max)

.458

.375

.187

.0157

.0027

.0098

.031

.118

Grade : IC8150

A hard substrate with a cobalt enriched layer, CVDcoating. Excellent thermal stability and resistan ce to chipping and plastic deformation. Recommended for high speed machining of steel at stable conditions.

ISO Range - P/M/K

(P01-P30)(K05-K15)

ISO Range - N/S/H

Grade or Coating Type

CVD

Coating Layers

TiCN+Al

2

O

3

+TiCN+TiN

Cutting Speed for: DNMG 331-F3P IC8150 - 5560576

ISO

Material

Material Designation

Material Condition

Hardness

Cutting Speed Recommendations (Vc)

P

1

Non-alloy steel and cast steel, free cutting steel <0.25% C

Annealed

125 HB

920-1380 sfm

P

2

Non-alloy steel and cast steel, free cutting steel >=0.25% C

Annealed

190 HB

785-1245 sfm

P

3

Non-alloy steel and cast steel, free cutting steel <0.55% C

Quenched and tempered

250 HB

755-1115 sfm

P

4

Non-alloy steel and cast steel, free cutting steel >=0.55% C

Annealed

220 HB

785-1180 sfm

P

5

Non-alloy steel and cast steel, free cutting steel >=0.55% C

Quenched and tempered.

300 HB

655-1050 sfm

P

6

Low alloy and cast steel (less than 5% of alloying elements)

Annealed

200 HB

655-1115 sfm

P

7

Low alloy and cast steel (less than 5% of alloying elements)

Quenched and tempered

275 HB

655-1050 sfm

P

8

Low alloy and cast steel (less than 5% of alloying elements)

Quenched and tempered

300 HB

625-985 sfm

P

9

Low alloy and cast steel (less than 5% of alloying elements)

Quenched and tempered

350 HB

590-920 sfm

P

10

High alloyed steel, cast steel and tool steel

Annealed

200 HB

655-985 sfm

P

11

High alloyed steel, cast steel and tool steel

Quenched and tempered

325 HB

590-920 sfm

P

12

Stainless steel and cast steel

Ferritic/martensitic

200 HB

720-1180 sfm

P

13

Stainless steel and cast steel

Martensitic

240 HB

785-1245 sfm